Kurumsal

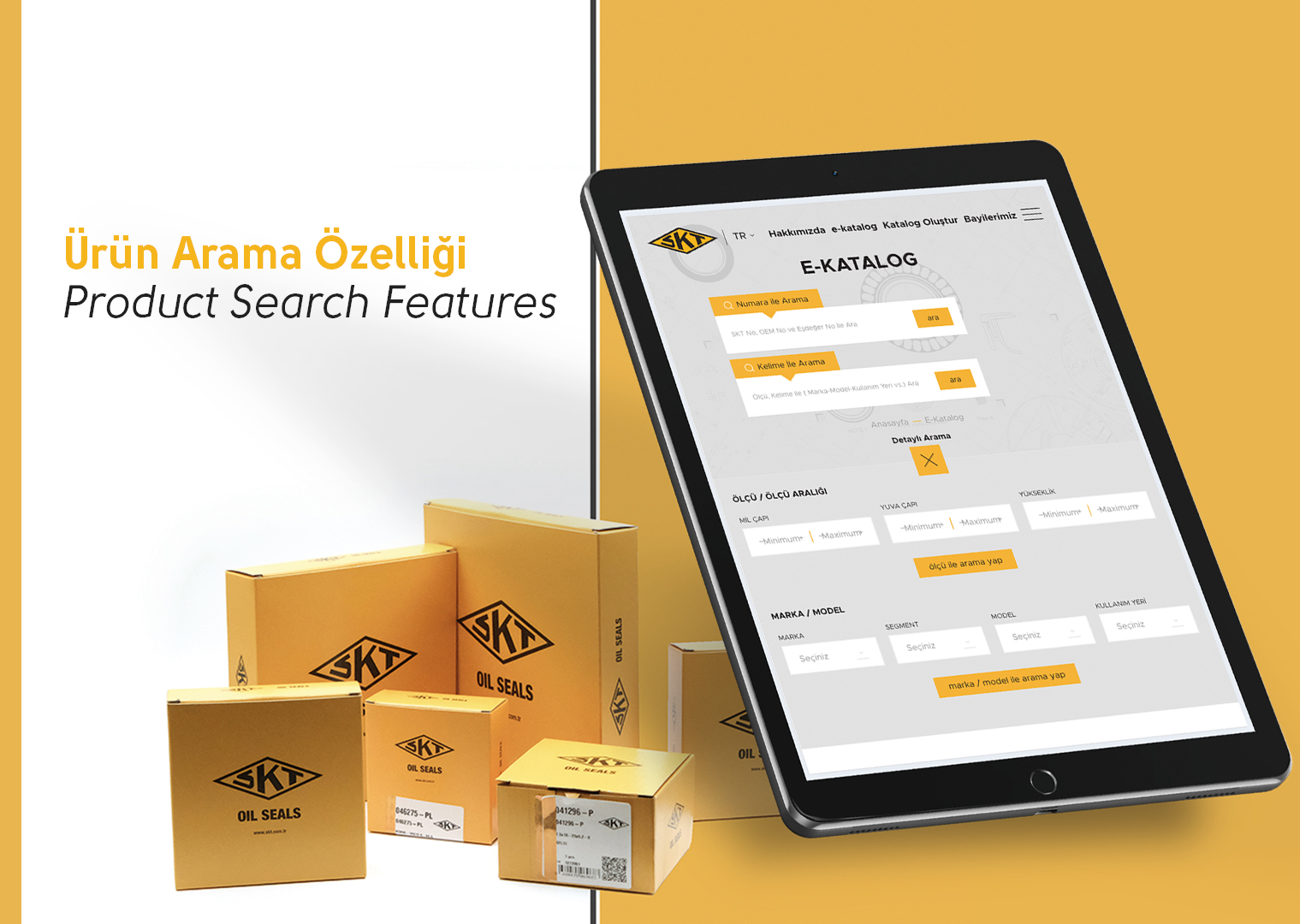

Ürünler

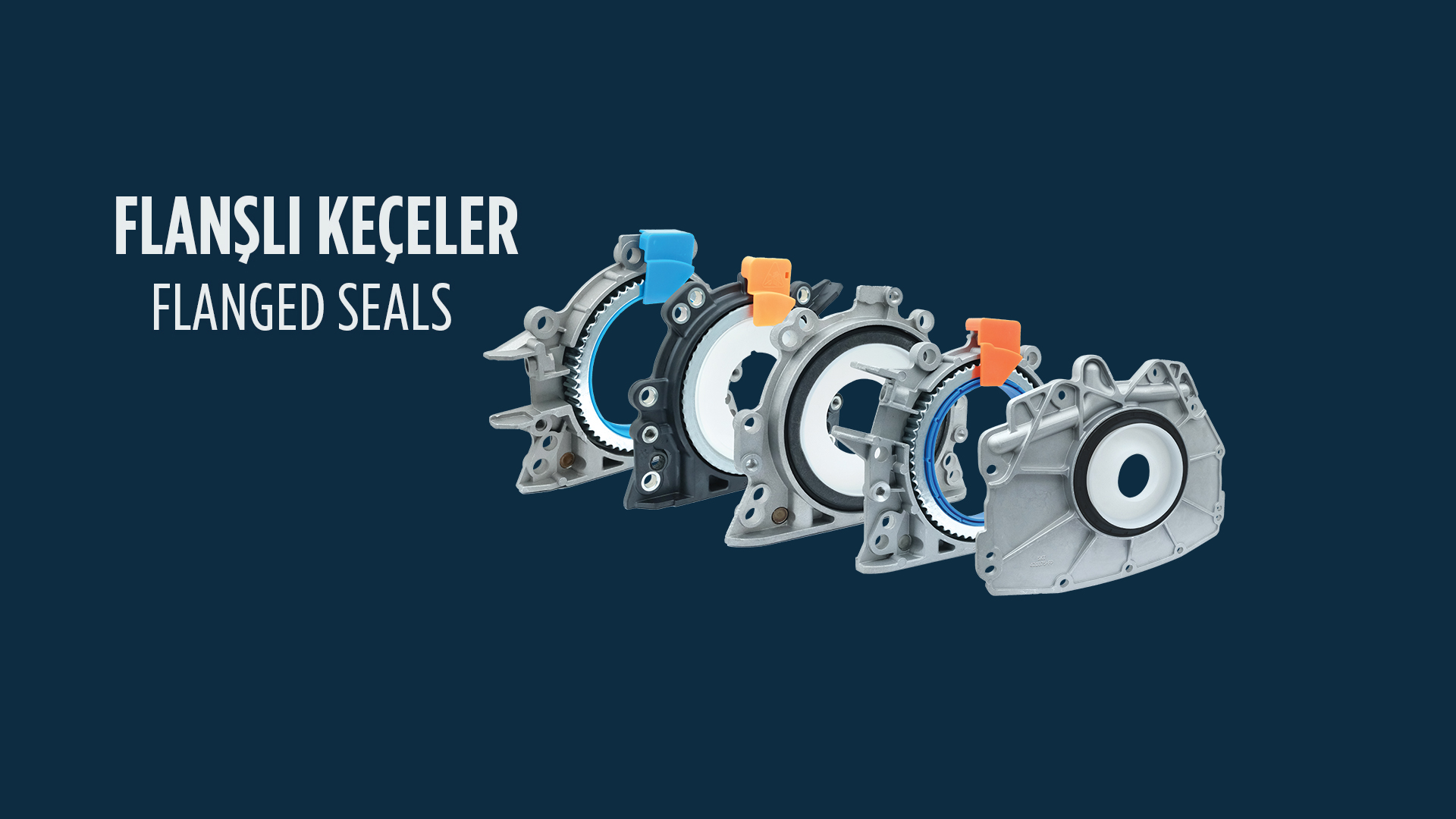

Döner Mil Keçeleri

Motor Conta Setleri

Diğer Sızdırmazlık Ürünleri

Yetkinlikler

Sürdürülebilirlik

Kurumsal İletişim

Basılı Materyallerimiz

İnsan Kaynakları

Bize Ulaşın